During this week Geoff and myself used the lens blank prepared by Neil Devil to cut a parabolic profile lens. Geoff coded a parabolic curve into the nano-lathe software to generate the .nc file for cutting. We ran a couple of rough passes with the diamond tool to create the curvature of the lens and then optically polished it with a finishing pass. Because we used acrylic, it was much faster than cutting the mirror facets. We completed the top side first and then flipped the lens to cut the other side.

This lens is hopefully the start of our venture into lens making! Geoff and myself are also working with Dr Noelia Martinez Ray to design more accurate curvatures for our lenses. The purpose of this lens is to project an image of the translucent slide so that it focuses just before the surface of the mirror facet.

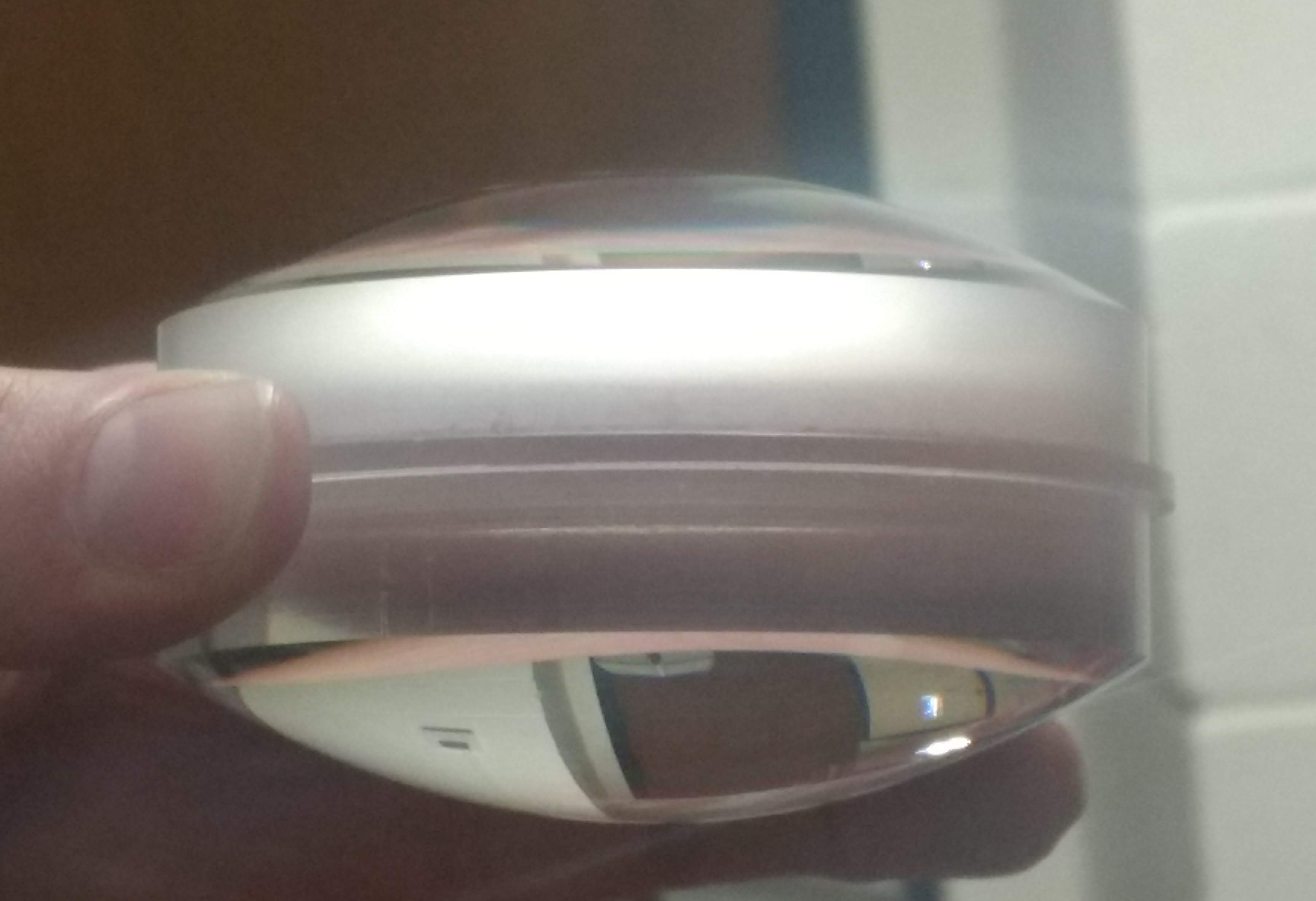

Both this projected image and the mirror surface are then projected though the objective lens into a combined single image, as per the images I have posted throughout the blog. Below are some images which document the process.